Collins r-390A

Click on a thumbnail to enter the gallery of high-resolution images. Please be patient as some of these images are large and may take some time to load!

R-390A Module Details

Collins IF Module: This photograph shows the side of the 455 kHz amplifier module from my latest R-390A. This module was actually manufactured by Collins. The lineage of the module is easily identified by the Collins stock number (540-7577-006) stenciled on the side just above the module’s serial number (3431). The large box just above the stock & serial number contains the Collins mechanical filters which give the R-390A its characteristically-superb selectivity. However, today many R-390A’s do not display the selectivity that was their hallmark for many years, as many of the mechanical filters have suffered from breakdown of the special foam that suspended the filter mechanism within the filter housing. This often causes the selectivity curve to skew to one side of the other, and in some cases may actually cause the filter to fail entirely.

Audio Module: In this photo of the audio module we see one of the most outwardly-visible cost reduction changes made to the R-390A. The original R-390 receiver included a front panel squelch control, which allowed the operator to silence the background noise on the R-390’s tuned frequency when no transmissions were being received. While this seems like a worthwhile control, however, in reality it wasn’t all that effective because the impulsive noise typical of HF communications would frequently “open” the squelch, compromising its usefulness. Therefore, when it came to cost reduction, this circuit was one of the first to be considered for deletion. The metal plate on the right-hand side of the photograph covers a tube socket for a 6C4 squelch tube (the tube number is actually stenciled on the chassis beneath this plate). Thus, squelch can be added to the R-390A, although there is no control on the front panel for this function.

Audio Module, Another Perspective: This photograph shows only a portion of the R-390A audio module. Specifically, we see the two audio transformers which provide a local 600-ohm audio output as well as a 600-ohm line output. Although we can’t see the serial and stock number as in the IF module above, this module is also manufactured by Collins radio. Both audio output transformers in this photo are silk-screened “Freed Transformer Co, Inc.” a company which was a preferred transformer source for many Collins products. Just above the right-hand transformer is a cylindrical component with a hold-down strap. This is one of two electrolytic filter capacitors which are an integral part of the R-390A power supply. The R-390/R390A design is somewhat unique in that these capacitors plug into octal tube sockets, thus allowing a field technician to easily replace one of these multiple-section capacitors without any de-soldering. In fact, the entire design of the R-390 and the R-390A was based on a requirement to minimize the number of instances in which it would be necessary to heat up a soldering iron to make repairs. The modular design, along with an excellent understanding of which components were likely to fail under continuous use, greatly simplified the field maintenance of these fine receivers.

Front Panel: Anyone who’s purchased an R-390 or R-390A has probably found that the front panel shows considerable wear from use, moving the receiver in and out of equipment racks, etc. Restoring the front panel can be a very straightforward process or it can be quite complicated. The main deciding factor is whether the receiver uses an engraved front panel or a silk screened panel. All R-390 and R-390A receivers made by Collins utilized engraved front panels, and other contractors may have taken this approach, but most opted for silk screened panels because it greatly simplified the manufacturing process.

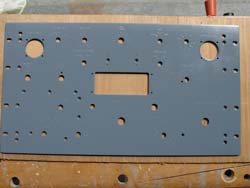

If you are fortunate enough to have an R-390 or R-390A with an engraved front panel, the panel can be sand blasted and repainted relatively easily. The photo above shows the front panel of my latest R-390A after sandblasting, priming with an aluminum primer, and a final coat of acrylic paint. All that’s remaining is to fill the engraving with water-based white paint. As you can see, this panel looks like new.

Digital Counter: When the R-390 was designed, the technology necessary to provide an electronic digital frequency display would have required additional hardware that would consume almost as much space and power as the R-390 itself. Instead of an electronic digital frequency counter, the Collins engineers took advantage of the R-390/R-390A’s excellent tuning linearity and used a mechanical digital frequency counter. While this counter, which was manufactured by the Veeder-Root Company, is intended to display the receiver’s operating frequency, it’s actually a mechanical readout of two key receiver aspects: (1) Which one of the receiver’s 32 bands is selected (displayed in the counter’s two most significant digits in MHz) and (2) the relative frequency (in kHz) of the receiver’s Permeability Tuned oscillator (PTO) in the display’s three least significant digits. On the far right you’ll notice small horizontal marks on the display. Each of these horizontal lines corresponds to a frequency change of 200 Hz. This level of tuning precision was unheard of in almost all receivers that preceded the R-390/ R-390A, and is impressive even by today’s standards when one considers the electromechanical design required. This level of precision was made possible through very exacting manufacturing tolerances in the design of the PTO and special linearizing cams, which allows the PTO to remain linear within less than 300 Hz across a 100 kHz tuning segment. The Collins PTO design is a classic example of excellence in engineering which I’ll touch upon when I have a chance to upload photos and text describing the PTO in more detail. In the meantime, you may want to read this excellent overview of the Collins PTO design as well as its internal construction.